Vanhu vazhinji vangasaziva mashandisiro emuchina wekuisa, tsanangura musimboti wemuchina wekuisa, uye kushanda kwakachengeteka. XLIN Indasitiri yave ichibatanidzwa zvakanyanya muindasitiri yemuchina yekuisa kwemakore gumi nemashanu. Nhasi, ini ndichagovera newe misimboti yekushanda uye yakachengeteka mashandiro emuchina wekuisa.

Muchina wekuisa: unozivikanwawo se "muchina wekukwira" uye "Surface Mount System", mumutsara wekugadzira, unogadziriswa mushure memuchina wekuparadzira kana muchina wekudhindisa skrini, uye iyo yekumisikidza system inoiswa nekufambisa musoro unokwira. Chishandiso chinoisa zvikamu paPCB pads. Muchina wekuisa musanganiswa wemuchina, magetsi, chiedza uye komputa yekudzora tekinoroji. Kuburikidza nekusveta, kutama, kuisa, kuisa uye mamwe mabasa, SMC / SMD zvikamu zvinogona kukurumidza uye zvakanamirwa zvakanamirwa kune yakatarwa padhi chinzvimbo chePCB pasina kukuvadza zvikamu uye yakadhindwa redunhu bhodhi.

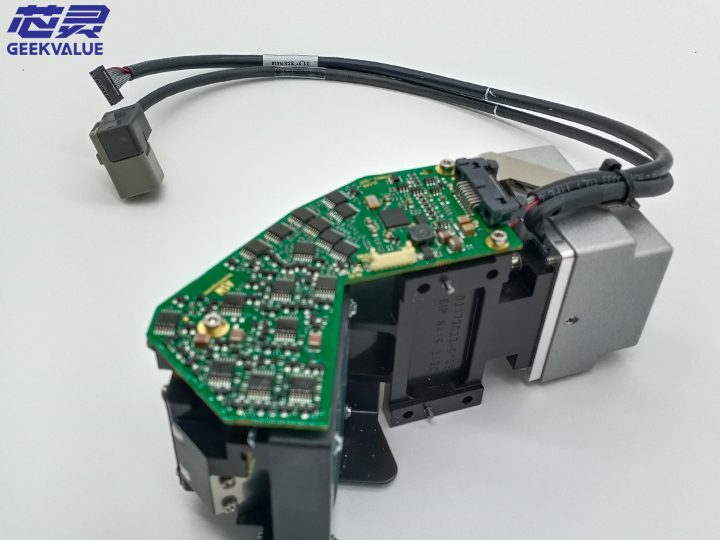

Pane nzira nhatu dzekuisa pakati pekuisa zvinhu pamushini wekuisa: mechanical centering, laser centering uye kuona centering. Muchina wekuisa une furemu, xy motion mechanism (ball screw, linear guide, drive motor), musoro wekuisa, component feeder, PCB inotakura michina, mudziyo wekuona dhizaini, uye komputa inodzora system. Kufamba kwemuchina wese kunonyanya kucherechedzwa neiyo xy kufamba mashandiro, simba rinofambiswa nebhora screw, uye mafambiro anotungamira anoonekwa neinotenderedza mutsara njanji. Iyi fomu yekufambisa haina kungoita kushoma kwekufamba, compact chimiro, asiwo yakanyanya kutapurirana kunyatsoita.

1. Kune marudzi maviri emichina yekuisa: manual uye zvizere otomatiki.

2. Nheyo: Iyo arch-type component feeder uye substrate (PCB) yakagadziriswa, uye musoro wekuisa (wakaiswa neakawanda vacuum suction nozzles) unofamba uchienda mberi nekudzoka pakati pekudyisa uye substrate kubvisa zvikamu kubva kune feeder. Rongedza chinzvimbo uye kutungamira, uye wozoinamatira pane substrate.

3. Nokuti chigamba chemusoro chakaiswa pa X / Y coordinate inofamba danda remhando yearch, saka inotumidzwa.

4. Nzira yekugadzirisa nzvimbo uye kutungamirirwa kwezvikamu zve arch type mounter: 1), gadzirisa nzvimbo yacho ne mechanical centering, uye gadzirisa hutungamiri kuburikidza nekutenderera muromo wekusveta. Kururama kwekuti nzira iyi inogona kubudirira ishoma, uye mienzaniso inotevera haisati yashandiswa.

5. Laser recognition, X/Y coordinate system kugadzirisa chinzvimbo, suction nozzle rotation adjustment direction, nzira iyi inogona kuziva chiziviso panguva yekubhururuka, asi haigone kushandiswa bhora regidhi yekuratidzira chikamu BGA.

6. Kuzivikanwa kwekamera, X/Y inoronga sisitimu yekugadzirisa chinzvimbo, yekuyamwa nozzle inotenderera gadziriso nzira, kazhinji kamera inogadziriswa, uye yekuisa musoro inobhururuka nepakamera kuti ionekwe kufungidzira, izvo zvinotora nguva yakati rebei kupfuura laser recognition, asi inogona kuziva. chero chikamu, uye kune zvakare mashandisirwo Iyo kamera yekuziva system yekuzivikanwa panguva yekubhururuka ine zvimwe zvibairo maererano nemakanika chimiro.

7. Mune chimiro ichi, nekuda kwechinhambwe chakareba chemusoro wechigamba chinofamba chichienda mberi nekudzoka, kukurumidza kunogumira.

8. Kazhinji, akawanda vacuum suction nozzles anoshandiswa kunhonga zvinhu panguva imwe chete (kusvika gumi) uye kaviri-beam sisitimu inoshandiswa kuwedzera kumhanya, ndiko kuti, musoro wekuisa pane rimwe danda riri kutora zvinhu, nepo musoro wekuisa pane rimwe danda uchinamira Chikamu chekuisa chinoda kuita kaviri kukurumidza seyomwe-beam system.

9. Zvisinei, mumashandisirwo anoshanda, zvakaoma kuwana mamiriro ekutora zvinhu panguva imwe chete, uye marudzi akasiyana-siyana ezvikamu zvinoda kuchinjwa nemhando dzakasiyana-siyana dzekusveta zviputi, uye pane nguva inononoka pakushandura mazamu ekusveta.

10. Iyo turret-type component feeder inoiswa pane imwe-coordinate inofamba zvinhu ngoro, iyo substrate (PCB) inoiswa pane worktable inofamba muX / Y coordinate system, uye musoro wekuisa unoiswa pane turret. Paunenge uchishanda, zvinhu zveMotokari inofambisa chikamu chekudyisa kunzvimbo yekunhonga, iyo vacuum yekusveta muromo wemusoro wechigamba inotora zvikamu panzvimbo yekunhonga, uye inotenderera ichienda kunzvimbo yekunhonga kuburikidza neturret (180). madhigirii kubva panzvimbo yekunhonga). Gadzirisa nzvimbo uye kutungamirirwa kwezvikamu, uye isa zvikamu pane substrate.

11. Kugadzirisa nzira yechikamu chechinzvimbo uye kutungamira: kucherechedzwa kwekamera, X / Y inoronga sisitimu chinzvimbo chekugadzirisa, suction nozzle self-rotation kugadzirisa kutungamira, yakagadziriswa kamera, yekuisa musoro uchibhururuka pamusoro pekamera yekuzivikanwa kwekufungidzira.

Pamusoro pezvo, muchina wekuisa unomaka zvikamu zvakakosha senge kukwirisa shafts, kufamba/kumira lenzi, zvinobatisa nozzle uye mafeeders. Chiono chemuchina chinogona kuverengera otomatiki kurongeka kweaya ekumaka masisitimu, kumisikidza hukama hwekushandura pakati peiyo inoronga sisitimu yemuchina wekuisa uye iyo yekubatanidza sisitimu yePCB uye akaiswa zvinhu, uye kuverenga iwo chaiwo marongero emuchina wekuisa. Musoro wekuisa unobata muromo wekusveta, uye unosveta zvikamu kunzvimbo inoenderana zvichienderana nerudzi rwepakeji, nhamba yechikamu uye mamwe maparamendi ezvakatengeswa kunze kwenyika zvikamu; iyo static lens inoona, inoziva uye inomisa zvikamu zvekusveta zvinoenderana nechirongwa chekuona chekugadzirisa; uye inopfuura nemumusoro unokwira mushure mekupedza Isa izvo zvikamu paPCB panzvimbo dzakafanotemerwa. Zviito zvakatevedzana senge chiziviso chechikamu, kurongeka, kuona, uye kuisirwa zvese zvinopedzwa otomatiki neiyo control system mushure mekunge komputa yeindasitiri yawana data rakakodzera zvinoenderana nemirairo inoenderana.

Muchina wekuisa mudziyo unoshandiswa kukwirisa-kumhanya uye yakakwirira-chaiyo yekuisa yezvikamu, uye ndiyo inonyanya kukosha uye yakaoma midziyo mukugadzirwa kweSMT yese. Mounter chigadzirwa chekuisa chip chinoshandiswa mukugadzira SMT. Muchina wekuisa ndewekuisa nemazvo muchina wekuisa munzvimbo inoenderana, wobva waunamira neglue dzvuku isati yaiswa uye solder paste, wozogadzirisa muchina wekuisa paPCB kuburikidza nehovhoni yekuyerera.

Iko kushanda kwakachengeteka kwemuchina wekuisa kunofanirwa kutevedzera anotevera ekutanga ekuchengetedza mitemo uye maitiro:

1. Simba rinofanira kuvharwa paunenge uchitarisa muchina, kutsiva zvikamu kana kugadzirisa uye kugadziriswa kwemukati (kuchengetedza kwemuchina kunofanira kuitwa nebhokisi rekukurumidzira rakatsikirirwa kana kuti simba rakabviswa.

2. Kana "kuverenga kurongeka" uye kugadzirisa muchina, iva nechokwadi chekuti YPU (programming unit) iri muruoko rwako kuitira kuti ugone kumisa muchina chero nguva.

3. Iva nechokwadi chokuti "interlock" midziyo yekuchengetedza inoramba ichishanda kuvhara chero nguva, uye kuongorora kwekuchengetedza kwemuchina hakugoni kusvetuka kana kupfupiswa, kana zvisina kudaro zviri nyore kukonzera njodzi dzemunhu kana dzemashini.

4. Panguva yekugadzirwa, mushandisi mumwe chete anobvumirwa kushandisa muchina mumwe.

5. Panguva yekushanda, iva nechokwadi chokuti zvikamu zvose zvemuviri, zvakadai semaoko nemusoro, zviri kunze kwekufamba kwemuchina.

6. Muchina unofanirwa kunyatsodzika pasi (chaizvo pasi, kwete kubatanidzwa kune neutral wire).

7. Usashandise muchina mune gasi kana nharaunda yakasviba zvakanyanya.

Nguva yekutumira: Zvita-17-2022